Tire Handling

Tire Landing Systems are engineered solutions designed to receive, cushion, and redirect tires at the end of conveyor lines, particularly in automated tire handling environments. Built for durability, precision, and flexibility, these systems ensure that tires land gently, maintain orientation, and are seamlessly transferred to the next stage—be it inspection, sorting, wrapping, or storage.

Our customizable tire landing solutions are tailored to specific tire sizes, weights, and handling speeds. Whether for passenger car tires, truck tires, or off-road variants, the system integrates with roller conveyors, belt systems, robotic arms, and automated sorters. Designed to reduce product damage and improve operator safety, they are ideal for modern tyre warehousing, distribution, and manufacturing facilities.

Shock-Absorbing Platform: Minimizes bounce and tire damage upon landing.

Custom Fit Design: Adjustable for various tire diameters and tread types.

Gentle Redirection: Ensures smooth transfer to next handling station.

Durable Construction: Built with heavy-duty materials for long-term operation.

Modular Integration: Works with existing conveyors, stackers, and sorters.

Optional Sensors: For automated detection, counting, and quality control.

Space-Efficient Layout: Configurable for linear or angular landing paths.

| Specification | Details |

|---|---|

| Tire Size Range | 12” to 120” |

| Weight Capacity | Up to 1000 kg per tyre |

| Landing Mechanism | Shock-absorbing chute or cushioned platform |

| Frame Material | MS with powder coating / SS (optional) |

| Integration Type | Roller, belt, or robotic system compatible |

| Orientation Control | Optional guide rollers or bumpers |

| Sensors & Controls | Photoelectric / Proximity / Load cell options |

Applications

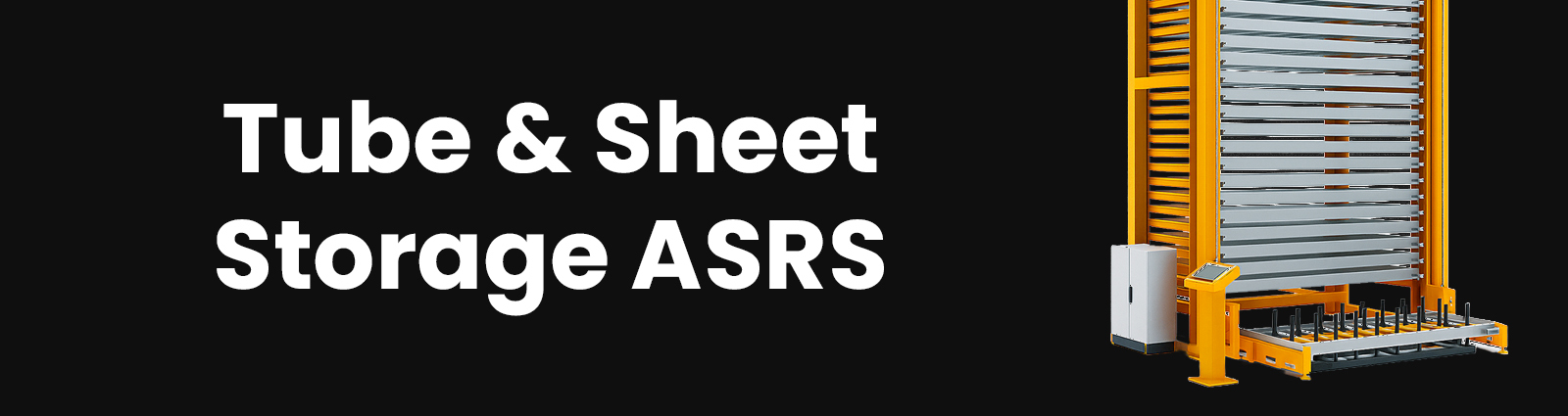

Tube & Sheet Storage ASRS

Tube & Sheet Storage ASRS is a high-density, automated material storage and retrieval solution engineered specifically for managing long profiles, pipes, metal tubes, and sheet metal in industrial environments. This smart system maximizes vertical and horizontal space, ensuring efficient inventory control, reduced retrieval time, and safer handling of heavy or bulky materials. By automating the storage process, it eliminates manual stacking, minimizes damage, and streamlines material flow to cutting machines, laser systems, or production lines.

Designed to integrate seamlessly with ERP and CNC systems, this ASRS solution provides real-time inventory tracking, fast pick times, and flexible tray configurations to suit a variety of metal stock profiles. Ideal for manufacturers, service centers, and fabricators, it enhances productivity, ensures operator safety, and supports lean storage practices.

Multi-Profile Compatibility: Stores tubes, pipes, rods, and sheet metal.

Vertical Space Optimization: Reduces warehouse footprint by up to 60%.

Automated Retrieval: Quick access via robotic shuttle or crane systems.

Smart Inventory Management: ERP-ready interface with tracking & alerts.

Heavy-Duty Tray System: Handles large dimensions and weight capacities.

Modular & Scalable: Easily expandable based on inventory needs.

Operator Safety: Minimizes manual lifting and material handling risks.

| Specification | Details |

|---|---|

| Load Capacity per Tray | Up to 3000 kg (customizable) |

| Tray Dimensions | Up to 6000 mm x 1500 mm (custom sizes available) |

| Material Types Supported | Steel, aluminum, copper, plastic sheets & tubes |

| Retrieval Speed | < 60 seconds per operation |

| System Height | 3 – 15 meters (modular) |

| Control System | PLC/SCADA with HMI interface or ERP integration |

| Safety Standards | EN ISO 12100, CE Certified |

Applications

Heavy Load Storage Solutions

Heavy Load Storage Solutions are engineered systems—ranging from heavy-duty pallet racking and drive-in/drive-through racks to high-bay ASRS, pallet‐shuttle lanes, and mobile bases—designed to safely store and retrieve loads weighing from 1 ton to 30 tons per pallet, cassette, or tray. Built from high-strength, cold-rolled or hot-rolled structural steel, these solutions maximize vertical and horizontal cube utilisation while maintaining full compliance with seismic and fire-safety standards.

Integrated with options such as shuttle cars, stacker cranes, automated guided forklifts, and WMS/ERP software, heavy-load systems reduce aisle count, speed up access times, cut labour costs, and eliminate damage associated with floor stacking or under-spec shelving. Ideal for steel service centers, foundries, and bulky-goods warehouses, they provide a future-proof platform for Industry 4.0 material-flow automation.

Extreme Load Capacity – Up to 30 t per location with reinforced uprights, box-beams, and bolted frame bracing.

Space Optimisation – High-bay designs (≥30 m) and double-deep or shuttle lanes cut required footprint by up to 60 %.

Automated Retrieval Ready – Compatible with stacker cranes, pallet shuttles, AGVs, and robotics for 24/7 lights-out operation.

Modular & Scalable – Bolted or welded frames allow phased expansion and easy reconfiguration of beam levels.

Safety & Compliance – Designed to EN 15512 / RMI / FEM 10.2.02, optional seismic footplates, impact-absorbing column guards, and fire-rated barriers.

Smart Monitoring – Optional load sensors, RFID location tracking, and cloud WMS integration for real-time inventory accuracy.

| Parameter | Value |

|---|---|

| Load per Location | 1 t – 30 t |

| Bay Width | 1100 – 2400 mm (adjustable) |

| Frame Height | 3 m – 30 m (high-bay) |

| Beam Type | Box-beam / I-beam / Tubular |

| Decking Options | Open bars, heavy plywood, hot-dip mesh, closed steel panels |

| Corrosion Protection | Powder coat RAL 9005 / HDG / epoxy marine paint |

| Automation Options | Shuttle cart, stacker crane, pallet lift, AGV interface |

| Standards | EN 15512, FEM 10.2.02, AISC, CE-marked |