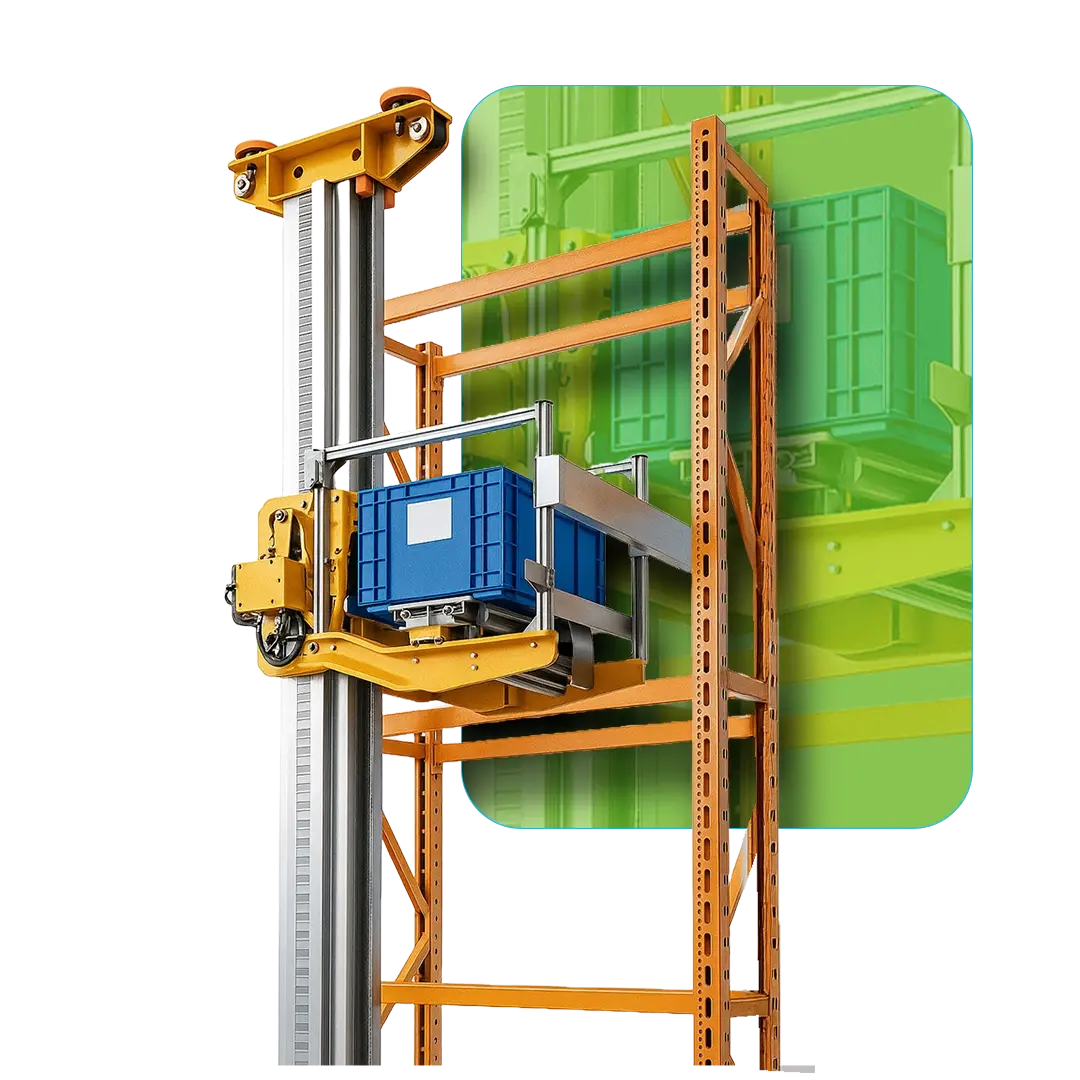

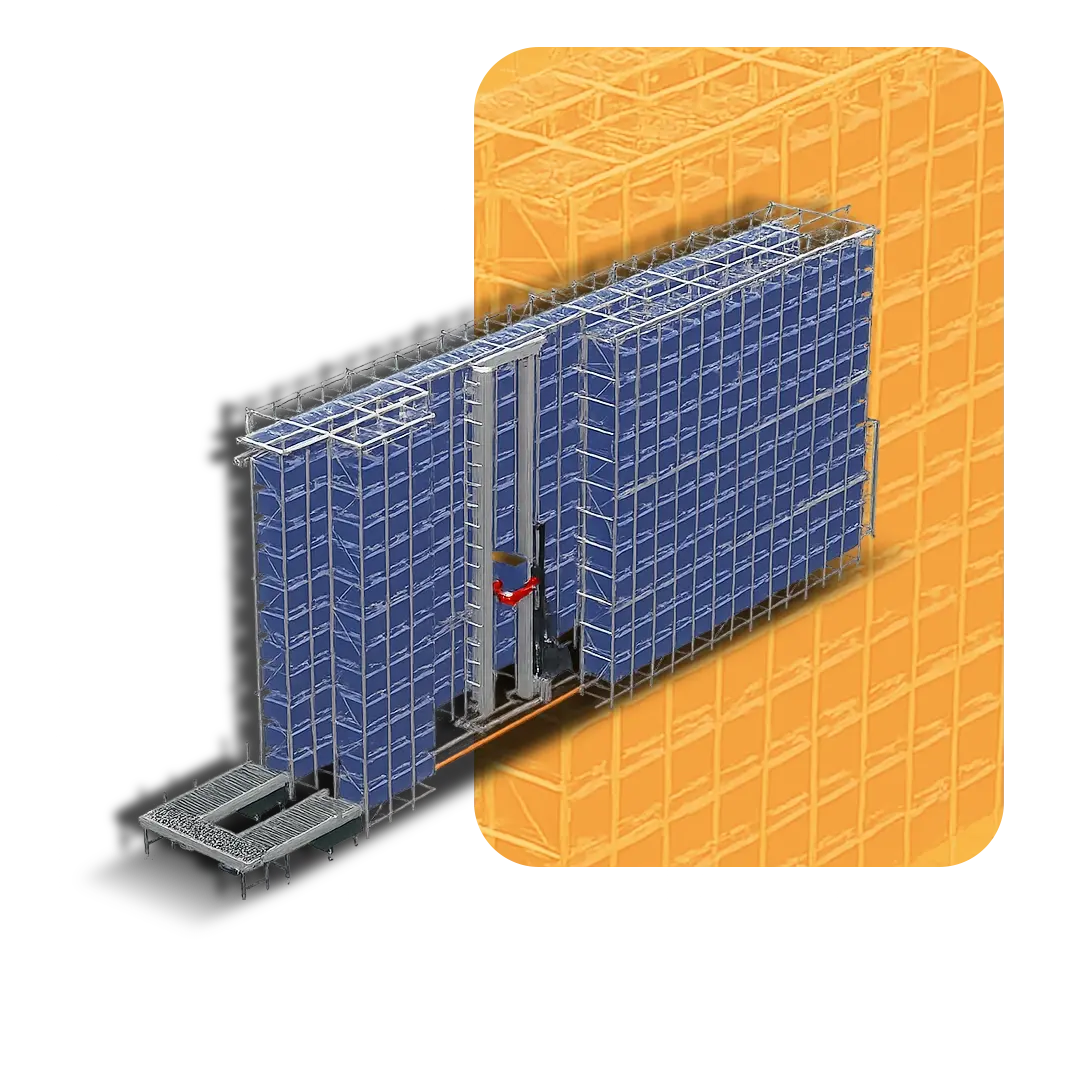

Mobi High Speed

The Mobi High Speed is a tote-handling solution that delivers high storage density with rapid and accurate picking. The Mobi travels horizontally and vertically on a lightweight frame supported by racks. Upon requests for a stored item, the Mobi picks up the tote containing the item from the rack and delivers to the station via conveyors or using AMRs.

Working of Mobi

Step 1 -When an order is received by the client’s WMS, Mobi travels to the tote location on rack that contains the item.

Step -2 The Mobi passes the tote to a floor AMR/ to conveyor, which then transfer the tote to picking station.

Step-3 Operator picks the items as per pick notification. If an order contains multiple SKUs, Mobi will have multiple totes brought to the operator to complete the order lines.

Step -4 The AMR / conveyor then returns the tote to infeed station, then Mobi picks the tote and allocates dynamic location inside the racks.

- High storage density

- High speed pick

- Scalable.

- Eco-friends – DC Power

- Less power consumptions – saving on electricity

- Can be customized to suit your bin size requirements.

- Can be installed in running warehousing – modular design.Industries served

- Tote size mm -L-600xW-400xH-400

- Max weight carrying capacity -30 kg

- Max SKU per tote -10-12 SKUS

- Max height of Mobi -8 to 10 meters.

- Aisle width -900 to 1000mm

- Speed -3 to 4 m/s

Applications

Logistics & Tyre Warehousing

Automotive OEMs

Unit Load ASRS

Unit Load ASRS is a high-capacity, automated warehousing solution designed for the efficient storage and retrieval of large, palletized loads or heavy unitized goods. It utilizes automated cranes (stacker cranes or SRMs) running along narrow aisles between high-density racking systems to handle unit loads weighing up to several tons—dramatically improving storage space utilization, throughput, and inventory accuracy.

By integrating with WMS/WCS platforms, a Unit Load ASRS automates tasks such as putaway, retrieval, inventory checks, and replenishment. This makes it ideal for operations requiring 24/7 reliability, secure storage, and real-time stock visibility, such as in manufacturing, cold storage, distribution, and raw material warehouses.

Multi-Profile Compatibility: Stores ISO/EURO pallet loads, can be customizable for other size off pallet loads.

Vertical Space Optimization: Reduces warehouse footprint by up to 60%.

Automated Retrieval: Quick access via robotic shuttle or crane systems.

Smart Inventory Management: ERP-ready interface with tracking & alerts.

Heavy Duty Fork Systems: Handles large dimensions and weight capacities.

Modular & Scalable: Easily expandable based on inventory needs.

Operator Safety: Minimizes manual lifting and material handling risks.

| Specification | Value |

|---|---|

| Load Type | Palletized goods / unitized containers |

| Max Load Capacity | Up to 2,000 kg per pallet |

| Storage Height | Up to 40 meters |

| Crane Speed (H/V) | Up to 200 m/min horizontal, 60 m/min vertical |

| Aisle Width | 1.5 – 2 meters (single or double-deep options) |

| Storage Density | 50%–85% space optimization compared to conventional racking |

| Operating Temp Range | -30°C to +55°C (cold storage compatible) |

| System Accuracy | ± 5 mm (placement/retrieval) |

| Software Integration | WMS, ERP, WCS, SCADA compatible |

Applications

FMCG & Packaged Goods

Cold Storage & Frozen Warehousing

Mobi Mini Load ASRS

A Mini Load ASRS is a compact and high-moderate speed automated storage solution designed specifically for the storage, retrieval, and handling of small parts, totes, cartons, or trays. These systems utilize shuttles or mini-load cranes that operate in narrow aisles between high-density racking to optimize space utilization and increase picking efficiency—making them ideal for order fulfilment, spare parts management, and high-SKU inventory operations.

Mini Load systems are perfect for operations where speed, accuracy, and space-saving are critical. By integrating with WMS or WCS platforms, Mini Load ASRS ensures real-time inventory control, order sequencing, and picking optimization, reducing labour dependency and operational errors.

- High-Speed Retrieval

Rapid access to small parts or totes with cycle times under 10-20 seconds. - Compact Footprint

Utilizes vertical space efficiently in tight warehouse areas. - SKU-Level Precision

Enables accurate retrieval for high-mix, low-volume SKU environments. - Multi-Depth Storage

Supports single-deep or double-deep rack configurations. - Integrated Software Control

Real-time synchronization with WMS/WCS for accurate inventory tracking. - Low Error Rate

Automated picking reduces human error and boosts order accuracy. - Modular & Scalable

Easily expandable as SKU count or order volume increases.

- High-Speed Retrieval

Load Type | Totes, trays, cartons (typically 50–300 mm height) |

Max Load per Carrier | Up to 50 -80kg |

Storage Height | Up to 18 meters |

Retrieval Speed | Horizontal: 200 m/min, Vertical: 100 m/min |

System Accuracy | ± 1–2 mm |

Throughput | 90–120 cycles/hour (per aisle crane) |

Racking Configuration | Single or double-deep |

Software Compatibility | WMS, WCS, ERP, SCADA systems |

Power Consumption | Energy-efficient motors with regenerative braking |

Applications

Cold Storage & Food Distribution

FMCG

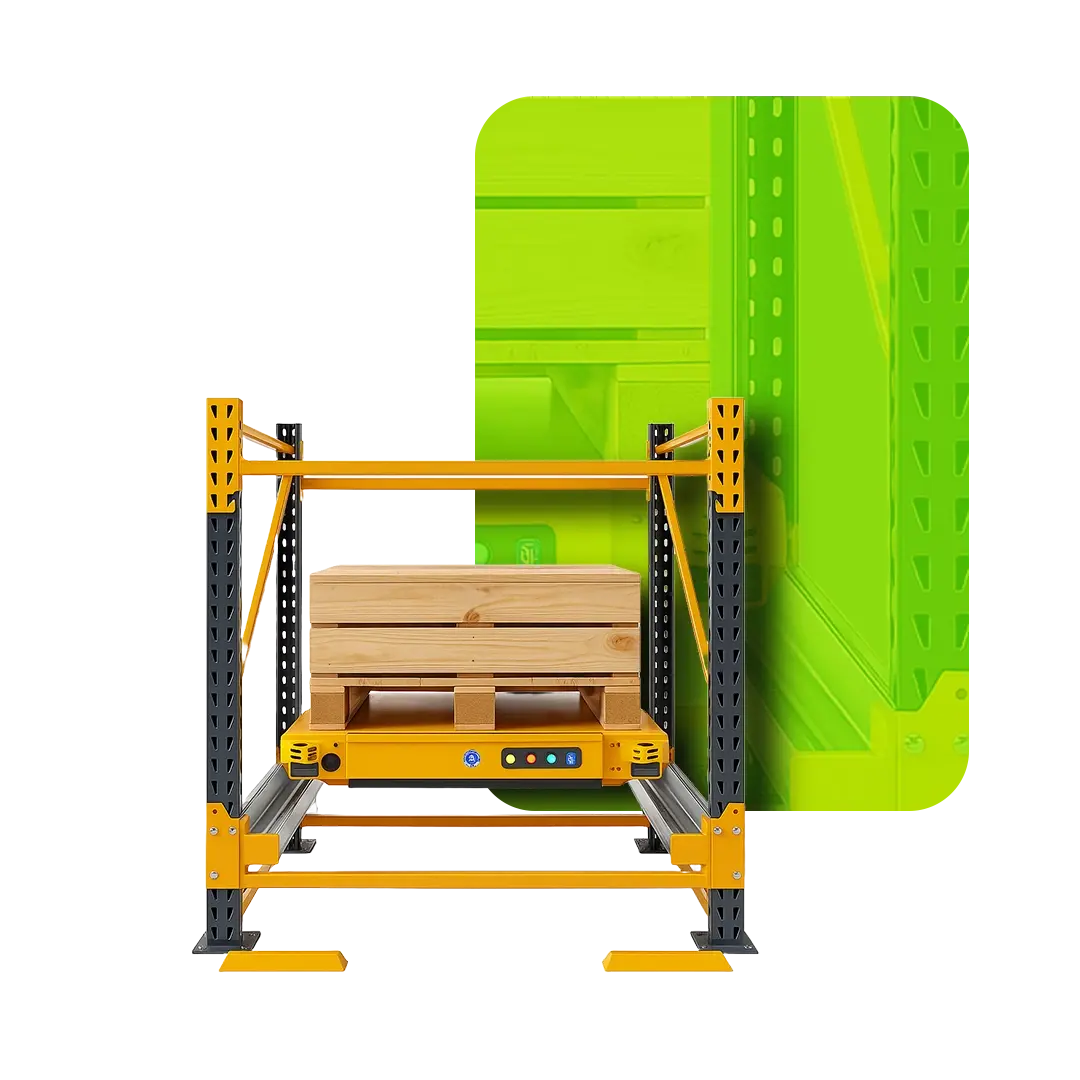

Pallet Shuttle

A Pallet Shuttle is a semi-automated or fully automated high-density storage system designed to move pallets within deep storage channels, reducing forklift travel time and maximizing space utilization. Instead of forklifts entering the racking system, a motorized shuttle runs on rails inside storage lanes to automatically pick up, transport, and deposit pallets, significantly enhancing efficiency and safety.

Controlled by a remote operator or fully integrated WMS, the pallet shuttle system allows FIFO/LIFO logic, real-time inventory visibility, and optimized throughput. It is ideal for cold storage, high-throughput warehouses, and environments where pallet turnover is fast and floor space is at a premium.

- High-Density Storage

Deep lane storage up to 40+ pallets deep increases warehouse capacity by up to 80%. - Motorized Shuttle Movement

Battery-powered shuttle transports pallets automatically within the racking. - FIFO / LIFO Compatible

Supports both inventory rotation strategies depending on operational needs. - Remote or WMS-Controlled Operation

Can be operated via handheld device or fully automated with WMS integration. - Reduced Forklift Movement

Improves safety and reduces damage by limiting forklift entry into racking. - Fast Cycle Times

Speeds up pallet put-away and retrieval, especially during peak volumes.

Load Type | Euro pallet / ISO pallet |

Max Load Capacity | Up to 1,500 kg per pallet |

Lane Depth | Up to 40 pallets per channel |

Shuttle Speed | Up to 80 m/min (loaded) |

Power Supply | Rechargeable lithium battery |

Operation Time | 8–10 hours per charge |

Operating Temperature | -20°C to +45°C (cold storage compatible) |

Control Mode | RF Remote / WMS Integration |

System Accuracy | ± 5 mm pallet positioning |

Applications

Mother and Child Shuttle

The Mother and Child Shuttle system is a highly advanced, fully automated pallet handling solution used in ultra high-density, multi-deep storage environments. It comprises two key components: the Mother Shuttle, which travels along the main aisle rails, and the Child Shuttle, which is deployed by the mother unit into specific storage channels to retrieve or place pallets. This two-level automation system enables fast, accurate, and high-volume movement of pallets with minimal human intervention.

Ideal for large distribution centres, cold storage, and high-throughput warehouses, this system provides unmatched storage efficiency, scalability, and operational speed. With full integration to Warehouse Management Systems (WMS) and Warehouse Control Systems (WCS), it offers real-time inventory control, intelligent pallet sequencing, and significant reduction in manpower and forklift traffic.

- Two-Tier Shuttle Operation

Mother shuttle carries and positions the child shuttle into storage lanes. - Ultra High-Density Storage

Multi-deep pallet storage—up to 40+ positions per lane and multiple levels high. - Fully Automated Pallet Handling

Eliminates forklift operation within storage zones, improving safety and speed. - FIFO / LIFO Logic Support

Flexible storage strategies for various operational models. - Real-Time Inventory Management

Seamless WMS/WCS integration ensures precise tracking and control. - Expandable & Scalable

Add more shuttles as demand grows without major reconfiguration. - Cold Storage Compatible

Robust design and components support operation in sub-zero environments.

Specification | Details |

|---|---|

Load Type | Palletized goods (Euro, ISO pallets) |

Max Load Capacity | Up to 2,000 kg per pallet |

Lane Depth | Up to 40+ pallets per channel |

System Height | Up to 20+ meters (multi-level racking) |

Mother Shuttle Speed | Up to 90 m/min |

Child Shuttle Speed | Up to 60 m/min |

Battery Life | 8–10 hours per charge; options for auto-charging |

Operating Temperature | -20°C to +50°C |

Control Integration | WMS/WCS, SCADA, and PLC compatible |

Safety Systems | Anti-collision, sensors, auto-failover, fire mode |

Applications

Vybe 4 Way Pallet Shuttle

The 4-Way Pallet Shuttle is a fully automated deep-lane pallet storage solution that moves pallets both inward and outward within racking channels along two directions—either front/back or left/right. Unlike traditional single-direction shuttles, the 2-way version enables bi-directional pallet transport, improving operational flexibility, reducing cycle time, and enhancing space utilization.

This system is ideal for high-density warehouses, cold storage facilities, and FIFO/LIFO inventory models, offering an excellent balance of automation and affordability. The shuttle is battery-operated and integrated with a Warehouse Control System (WCS) or Warehouse Management System (WMS) for synchronized pallet handling and real-time inventory management.

Bi-Directional Movement – Allows pallets to be stored and retrieved from either end of the channel.

High Storage Density – Reduces aisle requirements and increases pallet positions per square meter.

Remote or WMS-Controlled – Operated via WCS software integration and maintenance mode operation by using Tab.

Fast Turnaround Times – Reduces forklift travel and accelerates pallet put-away and retrieval.

Safety & Precision – Built-in sensors ensure accurate positioning, obstacle detection, and smooth braking.

Cold Storage Ready – Operates efficiently in sub-zero environments with insulated battery options.

Specification | Details |

|---|---|

Load Capacity | Up to 1,500 kg per pallet |

Travel Speed | Up to 90 m/min (loaded) |

Movement Type | Forward & Reverse / Left & Right based on layout |

Operation Mode | Semi-automated or integrated with WMS/WCS |

Power Source | Rechargeable lithium battery (8–10 hrs runtime) |

Lane Depth | Up to 40+ pallets per channel |

Operating Temperature | -20°C to +45°C |

Communication | RF, Bluetooth, or IoT protocols |

Safety Features | Anti-collision, auto-stop, system health monitoring |

Applications

Vertical Storage Unit

A Vertical Storage Unit (VSU)—also known as a Vertical Lift Module (VLM) or Vertical Carousel—is an advanced storage automation system designed to maximize vertical space while ensuring fast, ergonomic access to items. It operates by automatically retrieving trays stored in vertically stacked compartments and delivering them to an operator at an ergonomic access window, often using the “goods-to-person” picking principle.

Ideal for small parts, tools, documents, and inventory in high-density environments, VSUs significantly reduce floor space usage by up to 85%, improve picking accuracy, and speed up order fulfillment. With full integration to Warehouse Management Systems (WMS) or ERP software, it provides real-time inventory control and optimized picking logic.

- Maximized Vertical Space Usage

Utilizes ceiling height to increase storage capacity with minimal floor footprint. - Automated Retrieval System

Delivers selected trays to a single access point, eliminating walk-and-search time. - Ergonomic Operation

Tray delivery height can be customized for safe, fatigue-free access. - Inventory Security

Access-controlled compartments reduce unauthorized handling and losses. - Integrated Software Support

Works with WMS, ERP, or standalone software for inventory tracking, reordering, and reporting. - Customizable Tray Configuration

Adapts to varied load sizes—electronics, tools, pharmaceuticals, documents, etc.

Ray Load Capacity | Up to 1000kg per tray & customizable up to 3000kg |

Total Load Capacity | Up to 60,000 kg per unit (varies by model) |

System Height | From 2.5 m to 20+ m |

Tray Width Options | 900 mm to 4,000 mm |

Item Size Compatibility | Small parts to medium-sized items |

Access Control | RFID, PIN-based, or biometric (optional) |

Operation Mode | Manual, semi-automatic, or fully automated |

Temperature Range | 0°C to +45°C (climate-controlled options available) |

Safety Features | Light curtains, tray position sensors, emergency stops |