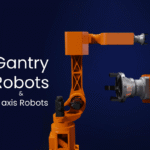

In continuation to our last blog on ‘Gantry robot – Everything about it & the applications of it’,

we thought of touching on an interesting caveat to these bots — they often get confused with 6-axis robots.

Both these mechanical workhorses play crucial roles in various applications, from intricate pick-and-place

tasks to heavy-duty material handling. Yet, distinguishing between them can be a common source of confusion.

In this blog, we’ll dive into the world of automation, shedding light on the differences between 6-axis and gantry robots.

Whether you’re a robotics enthusiast, involved in warehouse automation, or simply curious about industrial robotic applications,

this will help clarify the distinctions and their unique strengths. So, having learned what a gantry robot is,

now, let’s venture into what a 6-axis robot is.

6-axis / Articulated Robot:

A six-axis robot, also known as an articulated robot, has six degrees of freedom with rotational joints at each axis.

This allows it to move like a human arm — ideal for assembly, welding, painting, and material handling due to its flexibility and precision.

Why the confusion?

At a glance, both gantry and 6-axis robots seem similar due to their articulated joints and end-effectors.

Their overlapping functions and motion flexibility often blur the line, especially for those unfamiliar with their distinctions.

Let’s explore how they differ below:

Differences Between Six-Axis and Gantry Robots:

- 1. Scale: Gantry robots can be scaled easily by adding axes — offering more flexibility than 6-axis robots.

- 2. Reach: 6-axis robots operate within ~3m, ideal for tight spaces. Gantry robots can work across 30–40m, perfect for large workspaces and SKU handling.

- 3. Height: Gantry robots can be customized in height; 6-axis robots are height-limited.

- 4. Floor Space: Gantries consume less floor space, keeping layouts more open and efficient.

- 5. Maintenance: Gantries are linear and modular, making maintenance and part replacement easier.

- 6. Integration: Gantry robots are easier to install and integrate with minimal structural support.

- 7. Redundancy: Multiple gantries can operate on the same span — if one fails, another can take over seamlessly.

- 8. Applications: Gantries excel in pick-and-place, CNC, and material movement; 6-axis robots shine in welding, assembly, and tasks in tighter spaces.

Choosing the Right Robot:

The choice between gantry and 6-axis robots depends on workspace, budget, payload, and task type.

Each has pros and cons — assess thoroughly to choose the right fit.

Need Help?

We at Anzo Controls provide expert consultation and turnkey automation solutions including:

Gantry robots, Delta robots, SCARA robots, 6-axis robots, conveying systems, MES, and IoT integration.