Linear Gantry Palletizer

A Linear Gantry Palletizer is an advanced robotic system designed to automate the palletizing process by precisely picking and placing products onto pallets in a linear, programmable fashion. Unlike traditional robotic arms, the linear gantry system operates on X, Y, and Z axes, offering high-speed, high-load palletizing capabilities with exceptional accuracy and repeatability.

Ideal for high-throughput environments, this solution reduces manual labor, minimizes errors, and increases operational efficiency. With modular designs and custom gripper tools, the system can handle a wide variety of product types — from cartons, bags, and shrink-wrapped bundles to trays and crates. It integrates easily into existing production lines and is compatible with conveyors, stretch wrappers, AGVs, and WMS/ERP systems.

3-Axis Linear Motion: Controlled movement across X, Y, Z coordinates for precise layer forming.

Flexible Product Handling: Adapts to different product sizes, shapes, and stacking patterns.

Custom End-of-Arm Tooling (EOAT): Grippers for boxes, bags, trays, shrink packs, or fragile goods.

High Payload Capacity: Designed to handle up to 100 kg or more per pick.

Touchscreen HMI & PLC Integration: Easy-to-configure stacking patterns and pallet formats.

Automatic Pallet Handling: Pallet dispensing, centering, and conveying integration available.

Compact Footprint: Optimized layout for constrained warehouse or production environments.

| Specification | Details |

|---|---|

| Palletizing Speed | Up to 4 cycles/min (product-dependent) |

| Payload Capacity | Upto 500 Kg |

| Working Area | Customizable up to 10m x 2m x 3m |

| Axis Type | Linear gantry with servo or stepper drive |

| Position Accuracy | ±0.5 mm |

| Control System | PLC + HMI (Siemens / Allen-Bradley / Omron) |

| Integration Options | Conveyor, pallet dispenser, stretch wrapper |

| Power Supply | 3-phase AC, 400–480V, 50/60 Hz |

| Safety Features | Fencing, light curtains, emergency stops |

Applications

Strider Palletizing Robot

A Palletizing Robot is an intelligent, flexible automation solution that uses a robotic arm to stack a wide range of products—such as boxes, cartons, trays, bags, or drums—onto pallets with high precision and repeatability. Powered by multi-axis servo motors and programmable logic, palletizing robots can handle diverse product shapes and sizes while optimizing stacking patterns, pallet stability, and throughput.

These systems are ideal for end-of-line automation, especially in environments with high SKU variation or rapid changeovers. The robot can be integrated with vision systems, conveyors, pallet dispensers, stretch wrappers, and warehouse management systems (WMS) for full-line automation. Designed to reduce labor costs and improve safety, robotic palletizers also increase efficiency and consistency in packaging and logistics operations.

Multi-Axis Precision: 4, 5, or 6-axis robotic arm for flexible, high-accuracy stacking.

Smart Pattern Programming: Easily adjustable pallet configurations and product types.

Payload Versatility: Handles loads from 5 kg up to 300 kg or more per pick.

Compact Design: Small footprint with high stacking height capabilities.

Quick Changeovers: Supports frequent product or pattern changes with minimal downtime.

Vision Integration: For product detection, orientation, and quality checks.

Collaborative Options: Available in collaborative (cobot) formats for low-speed shared environments.

| Specification | Details |

|---|---|

| Axes | 4, 5, or 6 (articulated robot) |

| Payload Capacity | 5 kg – 300+ kg (depending on model) |

| Palletizing Speed | Up to 30 cycles/min (product dependent) |

| Reach | 1.5 – 3.1 meters (depending on configuration) |

| Control System | PLC/HMI or robot controller (ABB, Fanuc, KUKA, etc.) |

| Gripper Type | Vacuum, clamp, fork, bag, magnetic (customizable) |

| Safety Systems | Fencing, light curtains, emergency stop |

| Power Supply | 3-phase 400–480V, 50/60 Hz |

Applications

Bag Palletizer

A Bag Palletizer is a specialized automation system designed to efficiently stack filled bags—such as those containing cement, grains, fertilizer, sugar, or chemicals—onto pallets in a stable, uniform manner. Engineered for high speed, precision, and load integrity, the bag palletizer reduces the need for manual labor, minimizes workplace injury risk, and ensures consistent stacking for improved transport and storage.

Available in conventional, robotic, and gantry-style configurations, bag palletizers handle various bag types—polyethylene, jute, paper, woven fabric, or laminated bags—and are customizable for different weights, stacking patterns, and pallet sizes. The system can be seamlessly integrated with upstream bagging machines, check weighers, metal detectors, and downstream wrapping or strapping units.

High-Speed Operation: Handles up to 240-300 bags per hour depending on system type.

Custom Stacking Patterns: Configurable for column, interlocked, or mixed arrangements.

Heavy Load Handling: Supports bags from 5 kg to 100 kg.

Multi-Type Compatibility: Works with gusseted, valve, flat, or pillow-style bags.

Dust & Impact Control: Gentle handling minimizes product loss and packaging damage.

Compact Footprint: Space-efficient layout with modular expansion options.

HMI Control Panel: Easy recipe setup, real-time diagnostics, and safety alerts.

| Specification | Details |

|---|---|

| Bag Weight Range | 5 – 100 kg |

| Palletizing Speed | Up to 240-300 bags/hour (model dependent) |

| Bag Types Supported | Woven, Kraft paper, plastic, laminated |

| Stacking Accuracy | ±5 mm |

| Axis Type (for robotic) | 4 or 6-axis robotic arm / linear gantry |

| Control System | PLC + HMI (Siemens, Allen-Bradley, Delta) |

| Pallet Size Compatibility | 800×1200 mm, 1000×1200 mm, customizable |

| Safety Features | Light curtains, fences, emergency stop systems |

Applications

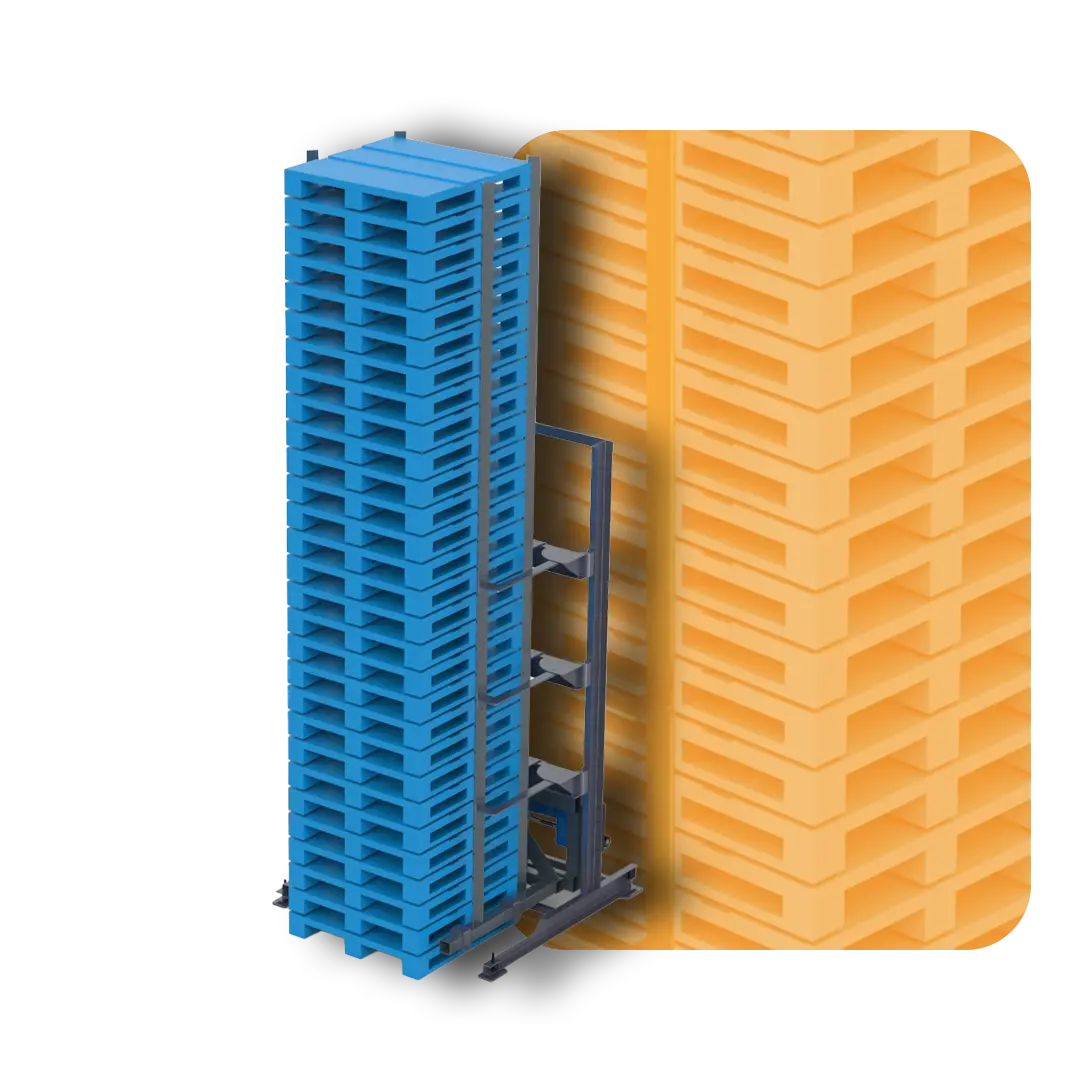

Stacker/De-Stacker

A Stacker/De-Stacker is an automated system used to efficiently stack or separate empty pallets, crates, bins, trays, or sheets, streamlining the material handling process in warehouses, packaging lines, and production areas. The system reduces manual effort, minimizes downtime, and enhances workplace safety by automating repetitive lifting tasks.

It is ideal for operations with high pallet turnover or crate-based handling, allowing for uninterrupted feeding or collection of materials. Often integrated with conveyors or robotic systems, a stacker/de-stacker is essential for automated palletizing, packing, and end-of-line logistics.

Automatic Stacking & De-Stacking

Handles a wide range of materials such as pallets, bins, crates, or trays.Customizable Height & Count

Programmable stacking levels and cycle counts for flexible operations.Heavy-Duty Structure

Designed for continuous, industrial-grade operation with minimal wear.Sensor-Based Detection

Ensures precise alignment and jam prevention.Smooth Integration

Connects seamlessly with conveyors, palletizers, AGVs, or robotic arms.

| Specification | Details |

|---|---|

| Load Types | Pallets, bins, crates, trays, sheets |

| Stack Height Capacity | Customizable up to 22+ pallets |

| Cycle Time | 10–15 seconds per stack/de-stack cycle |

| Load Capacity | Up to 1,200 kg per unit |

| Control System | PLC-based with HMI interface |

| Power Supply | 3 Phase, 415V AC / Optional servo drive |

| Integration Options | With WMS/WCS, palletizing, conveyor systems |