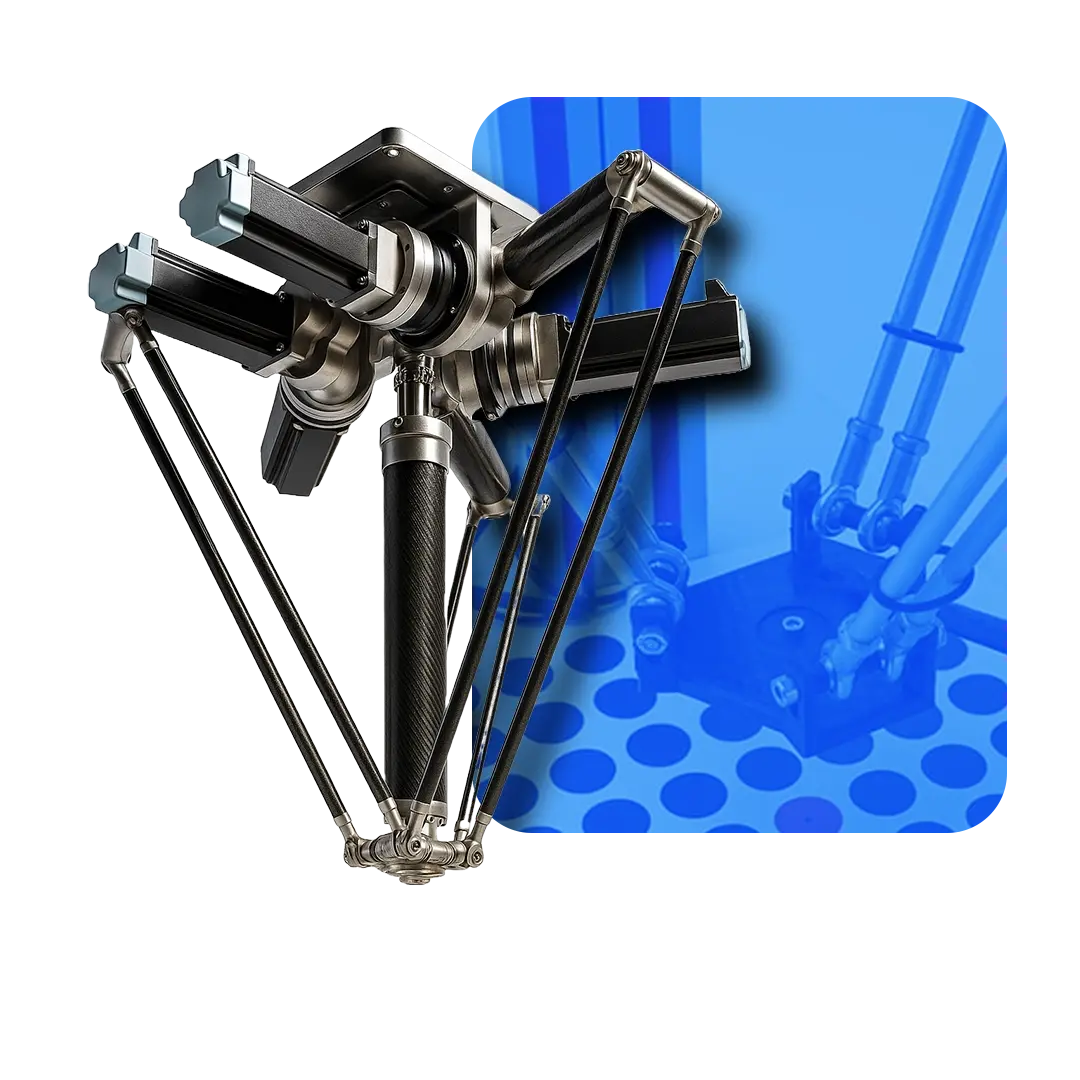

Delta Robots

Delta Robots are ultra-fast, high-precision robotic systems built for pick-and-place, sorting, packaging, and assembly tasks in high-throughput environments. With their unique parallel-arm design mounted overhead, delta robots offer unmatched speed, low inertia, and high repeatability—making them ideal for handling small, lightweight items at extremely fast cycle rates.

Operating in 3 or 4 axes (including rotation), these robots excel in primary and secondary packaging tasks, especially in industries like food, pharmaceuticals, electronics, and cosmetics. Delta robots can be seamlessly integrated with vision systems for tracking moving products on conveyors, ensuring real-time adaptability and consistent product orientation during operation.

High-Speed Pick & Place: Up to 30-50 picks per minutes depending on payload.

Lightweight & Compact: Overhead-mount design reduces floor space usage.

4-Axis Motion (Optional): Adds rotation for product orientation.

Vision System Integration: Real-time tracking on moving conveyors.

Low Inertia, High Repeatability: Ideal for fragile and lightweight items.

Hygienic & Washdown Versions: Available for food and pharma environments.

| Specification | Details |

|---|---|

| Axes | 3 or 4 (optional rotation) |

| Payload Capacity | Up to 30 kg |

| Reach | 800 – 1600 mm (diameter) |

| Repeatability | ±0.1 mm |

| Cycle Time | Up to 150–300 cycles/minute |

| Mounting Type | Overhead |

| Controller | Dedicated robot controller / integrated with PLC |

| Vision System Support | Yes – 2D/3D camera integration |

| Cleanroom Compliance | ISO 5 / IP65–IP69K (on request) |

Applications

Robotic Pick & Place

Robotic Pick & Place Systems are high-speed automation solutions designed to identify, grip, and move items from one location to another with precision and consistency. These systems are powered by articulated, SCARA, delta, or cartesian robots and are often paired with machine vision to detect object location, orientation, and sorting criteria in real time.

Whether moving components from a conveyor into packaging trays, sorting items by type, or transferring parts between workstations, pick & place robots dramatically increase production efficiency, accuracy, and throughput, while reducing labor costs and error rates. Designed for 24/7 operation, they are scalable for both high-speed and high-precision manufacturing lines.

High-Speed Precision: Handles up to 300 picks/min depending on robot type and payload.

Multi-Robot Options: Delta, SCARA, articulated, and gantry configurations available.

Vision System Integration: Real-time tracking and adaptive sorting.

Flexible Gripper Systems: Vacuum, mechanical, magnetic, or custom EOAT (End of Arm Tooling).

Compact Footprint: Integrates easily into existing production lines.

Repeatability & Reliability: Operates continuously with minimal maintenance.

| Specification | Details |

|---|---|

| Robot Types | Delta, SCARA, 6-axis, Cartesian |

| Payload Capacity | 0.5 kg – 50 kg+ (model dependent) |

| Cycle Rate | Up to 300 cycles/min (lightweight parts) |

| Position Accuracy | ±0.02 – ±0.1 mm |

| Vision Integration | 2D/3D camera systems for dynamic pick points |

| Communication Interfaces | Modbus, Ethernet/IP, Profinet, OPC UA |

| Safety Features | Light curtains, area scanners, emergency stop |

| Cleanroom Compliance | ISO Class 5–7 options (for pharma, electronics, etc.) |

Applications

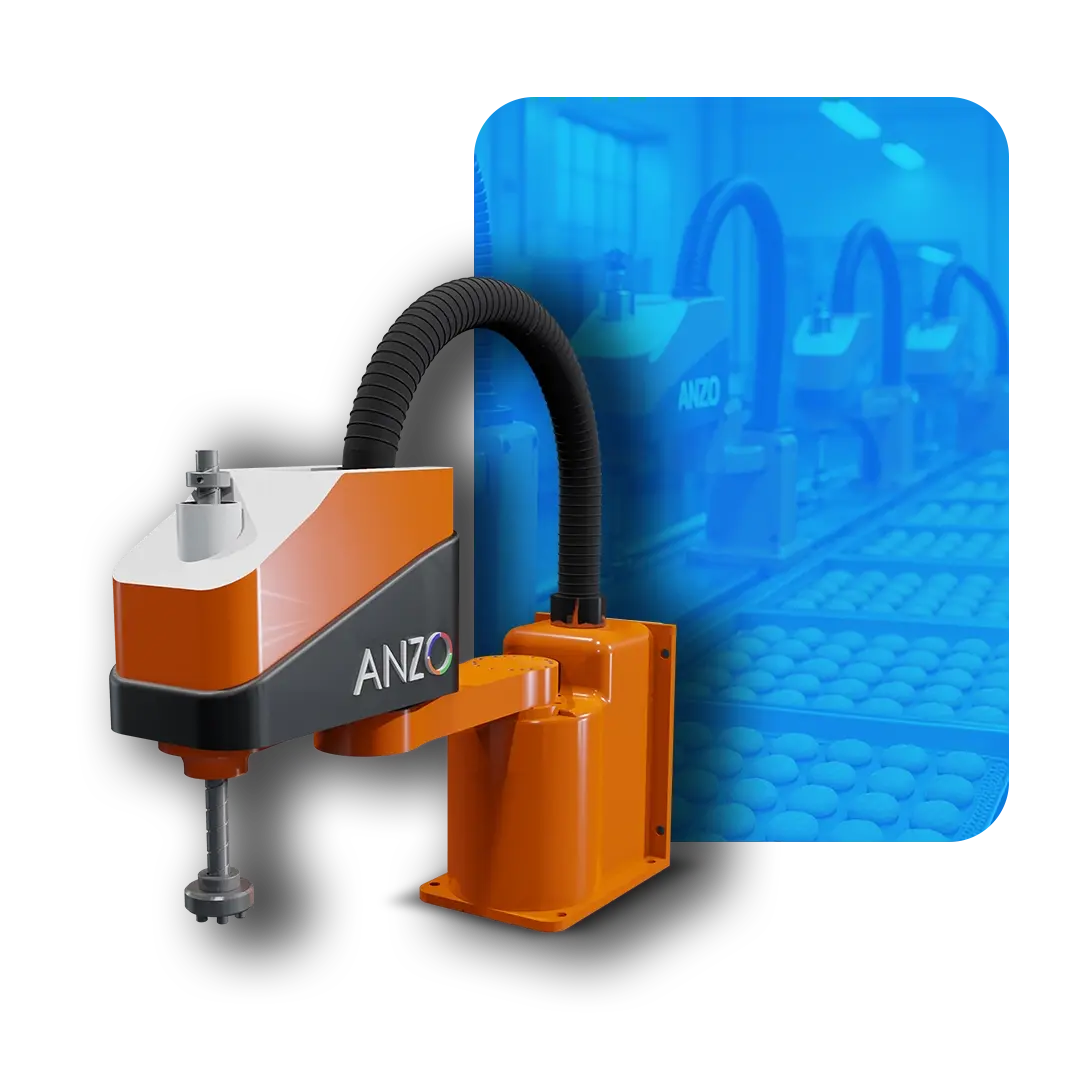

Scara

SCARA (Selective Compliance Articulated Robot Arm) Robots are fast, precise, and highly repeatable robotic systems widely used for pick-and-place, assembly, screw tightening, and small part handling tasks. Designed with a rigid vertical axis and flexible horizontal movement, SCARA robots are ideal for operations that require lateral precision with limited vertical compliance.

Thanks to their compact footprint and high-speed movement, SCARA robots excel in high-throughput manufacturing environments, especially where space and speed are critical. They can be easily integrated with vision systems, conveyors, and PLC/HMI controls for seamless automation and intelligent motion control.

4-Axis Precision Motion: Ideal for horizontal assembly and pick-and-place.

High-Speed Operation: Cycle times as low as 0.3 seconds.

Compact & Rigid Design: Perfect for tight spaces and dense production lines.

Easy Programming & Integration: Supports common industrial protocols and platforms.

Vision System Ready: Seamless integration for smart sorting and orientation.

Cleanroom Options: Available for medical, food, and electronics environments.

| Specification | Details |

|---|---|

| Axes | 4 (X, Y, Z, and rotation) |

| Payload Capacity | Up to 20 kg |

| Horizontal Reach | 300 – 1000 mm (model dependent) |

| Repeatability | ±0.01 – ±0.02 mm |

| Cycle Time | 0.3 – 0.5 seconds (no load) |

| Mounting Options | Tabletop or wall-mounted |

| Control System | Integrated PLC/HMI or robot controller |

| Communication Interfaces | Ethernet/IP, Modbus, Profinet, OPC-UA |

| Cleanroom Rating (optional) | ISO Class 5 – 7 |

Applications

Gama Pick & Place Gantry

A Pick & Place Gantry System is a linear robotic solution designed for high-precision horizontal and vertical product movement, used to pick items from one location and place them into another across a defined grid or workspace. Built on X, Y, and Z-axis motion control, this system provides accurate, stable, and repeatable operations, making it ideal for handling components that require precise placement, heavy payload handling, or long travel distances.

Unlike articulated or SCARA robots, gantry robots offer larger working envelopes, better structural rigidity, and excellent scalability. They can be fitted with custom grippers, vacuum heads, or magnetic tools, and are often used in industrial automation, machine tending, assembly lines, and material transfer operations.

Multi-Axis Precision: Operates on X, Y, Z axes with optional rotation (R-axis).

Customizable Travel Ranges: Designed to fit any workspace, from small to large-scale.

Heavy Load Handling: Capable of carrying payloads from a few kg to several hundred kg.

Programmable Logic Control: Integrated with PLC, HMI, and sensors for intelligent automation.

Custom End-Effectors: Supports vacuum, magnetic, clamp, or mechanical grippers.

Rigid Structure: High-speed operation with minimal vibration or positioning error.

Scalable Architecture: Easily expandable in length, width, or height as per production needs.

| Specification | Details |

|---|---|

| Motion Axes | 3-axis (X, Y, Z) or 4-axis (with rotation) |

| Payload Capacity | Up to 1000 kgs |

| Position Accuracy | ±0.1 – ±0.5 mm |

| Repeatability | ±0.05 mm |

| Travel Range | Customizable: from 0.5 m to 10 m+ |

| Speed | Up to 2 m/s (application dependent) |

| Control System | PLC + HMI or PC-based control |

| Communication Protocols | Modbus, Ethernet/IP, Profinet, OPC-UA |

| Safety Features | Emergency stops, light curtains, safety fencing |

Applications

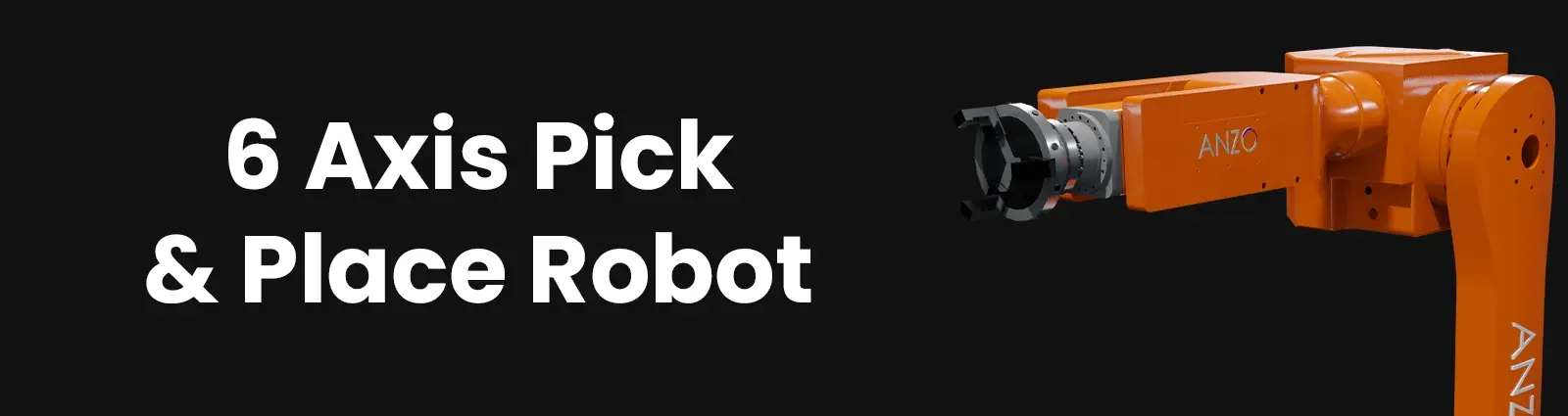

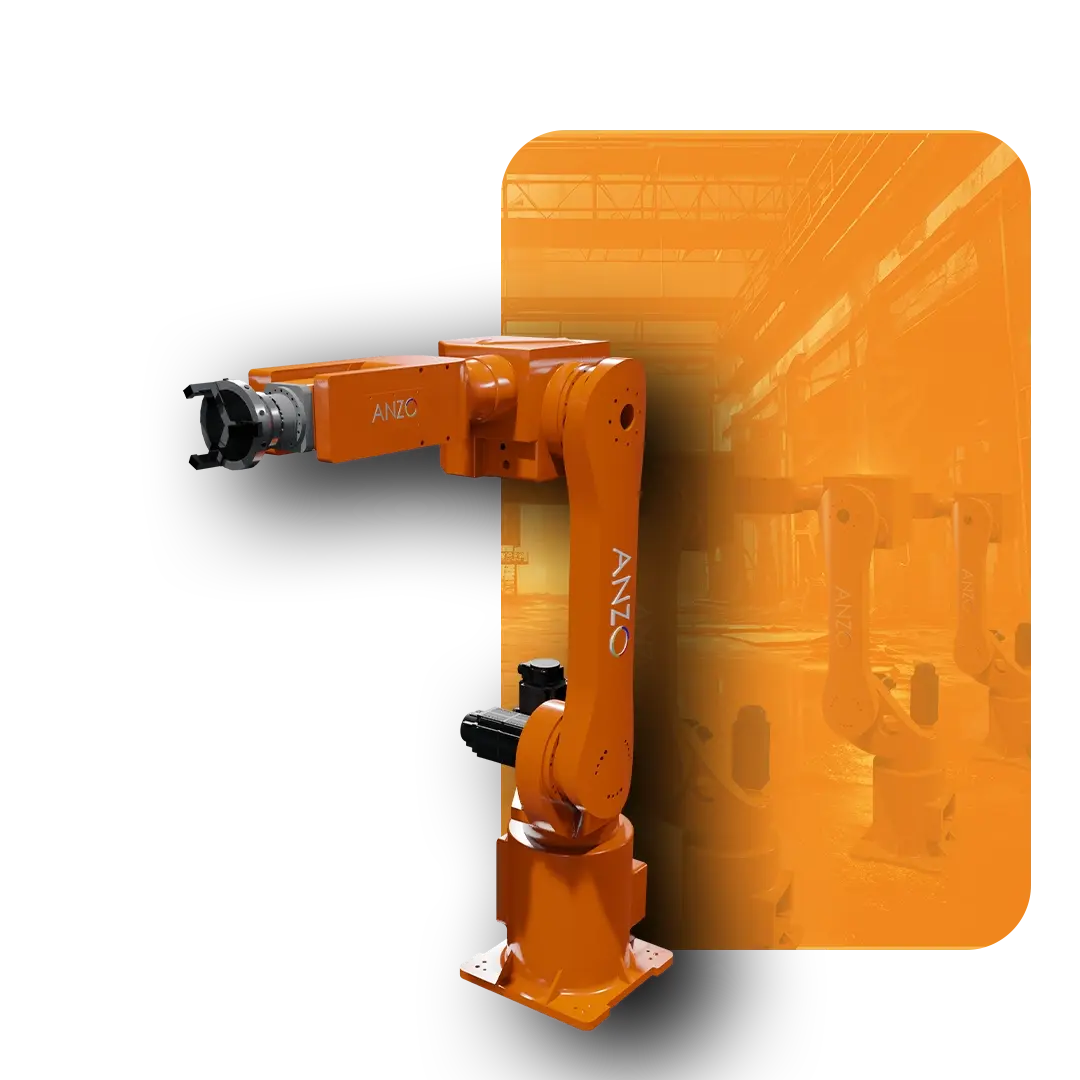

6 Axis Pick and Place Robot

The 6-Axis Pick and Place Robot is a high-precision robotic arm designed for complex and flexible automation tasks, capable of reaching, rotating, and orienting objects in all directions across six degrees of freedom. Unlike traditional linear pick-and-place systems, this robot mimics human arm movements, enabling it to handle varied parts, perform intricate motions, and adapt to multi-surface environments with ease.

Ideal for applications requiring speed, accuracy, and repeatability, such as assembly, sorting, inspection, packaging, and machine tending, the 6-axis robot reduces labor dependency while improving throughput and consistency. Integrated with vision systems, end-effectors, and PLC/WMS controls, it becomes a core component of Industry 4.0-ready smart manufacturing systems.

Six Degrees of Freedom

Allows full-range movement (up/down, left/right, forward/back, pitch, yaw, and roll).High Speed and Repeatability

Operates at fast cycle times with precision up to ±0.02 mm.Payload Flexibility

Available in multiple payload options from 3 kg to 50+ kg.Smart End-Effector Integration

Compatible with grippers, suction cups, welding torches, or custom tooling.Vision-Guided Operation

Can be paired with cameras or sensors for object detection and quality inspection.User-Friendly Programming

Supports teaching pendants, drag-and-drop HMI, or offline software programming.Compact & Space Efficient

Can be wall-mounted, ceiling-mounted, or floor-mounted for tight workspaces.

| Specification | Details |

|---|---|

| Axes | 6 (articulated arm) |

| Payload Capacity | 3 kg to 50+ kg (model-dependent) |

| Reach | 500 mm to 2,000 mm |

| Repeatability | ± 0.02 – 0.05 mm |

| Mounting Options | Floor / Wall / Inverted / Overhead |

| Control Interface | PLC / HMI / SCADA / Robot Controller |

| Power Supply | 220V or 400V AC, 3-phase |

| Communication Protocols | Ethernet/IP, Modbus, Profibus, Profinet, etc. |

| Safety Compliance | CE, ISO 10218, optional collaborative robot models |

Applications

4 Axis Delta Robot

A high-speed, high-precision 4-axis delta robot designed for advanced pick-and-place, sorting, and packaging operations. It delivers fast cycle times and supports complex stacking patterns for maximum efficiency.

With exceptional speed and a large working envelope, it is ideal for high-throughput applications such as secondary packaging, shelf-ready packaging, and retail-ready packaging. Its hygienic construction, use of FDA-compliant materials, and food-grade lubricants make it suitable for food, beverage, and pharmaceutical environments.

Integrated with intelligent control software and digital twin capabilities, the system enables rapid deployment, quick product changeovers, and seamless integration with conveyors and other end-of-line automation. Robust sealed joints and a durable structure ensure consistent performance, reduced manual labor, and reliable handling across diverse product formats.

Multi-Axis Control: Smooth motion on X, Y, and Z axes for accurate pallet stacking.

High Payload Capacity: Handles loads up to 150 kg or more per cycle.

Customizable Gripper Heads: Vacuum, clamp, fork, or magnetic heads for various product types.

Multi-Line Handling: Capable of palletizing from several product lines simultaneously.

Pre-Programmed Stacking Patterns: Easy setup for different SKUs, pallet types, and formats.

Durable Structure: Rigid steel gantry construction ensures long life and stable operation.

Modular Design: Expandable layout suitable for evolving operational needs.

| Specification | Details |

|---|---|

| Working Area | Up to 12m (X) × 3m (Y) × 3m (Z), customizable |

| Payload per Pick | Up to 150 kg |

| Cycle Speed | Up to 10–15 cycles/minute |

| Accuracy | ±1 mm |

| Axis Control | Servo or Stepper Motor with Encoders |

| Controller | PLC + Touchscreen HMI (Siemens/Omron/AB) |

| Power Supply | 3-phase, 400–480V AC, 50/60 Hz |

| Safety Systems | Light curtains, fencing, emergency stop buttons |