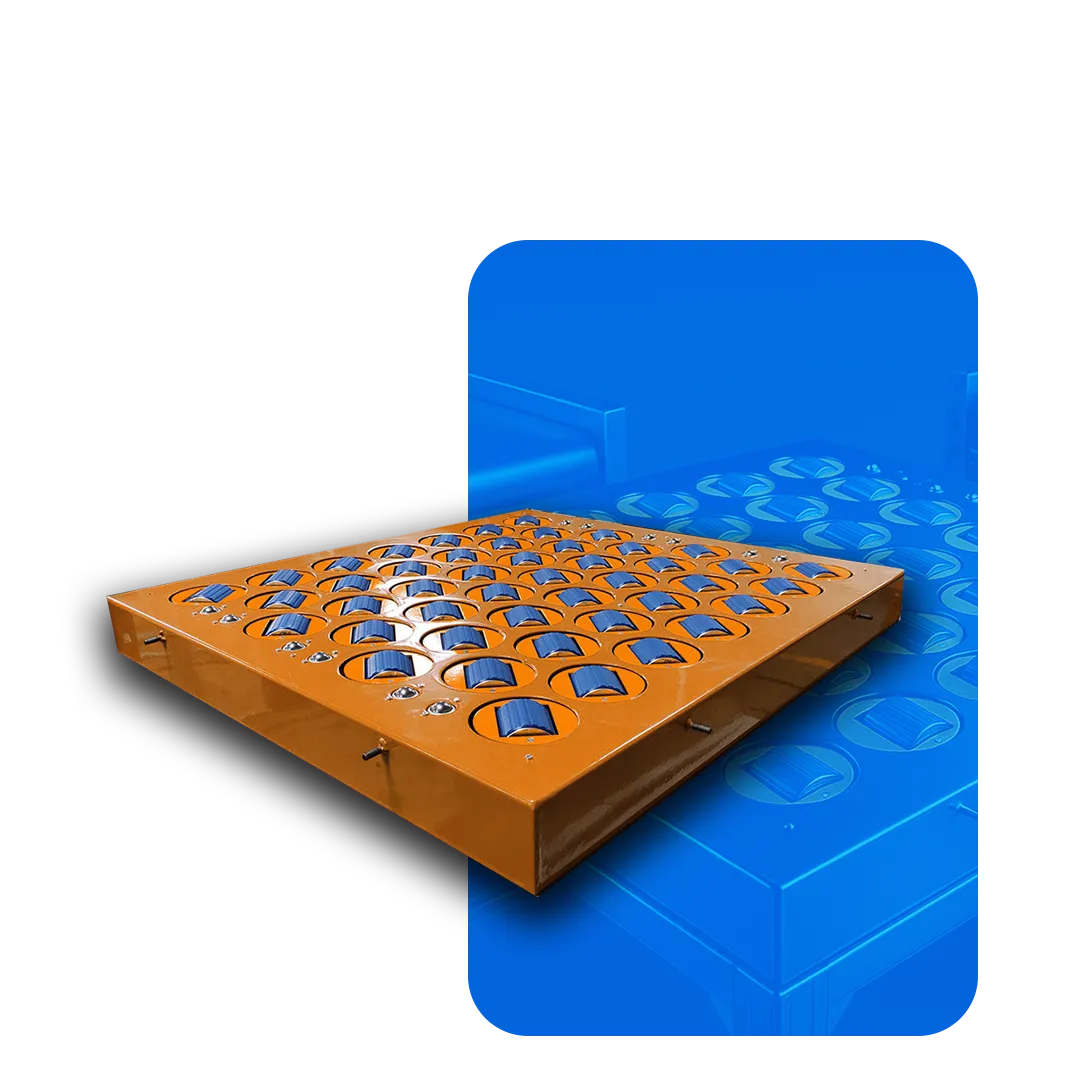

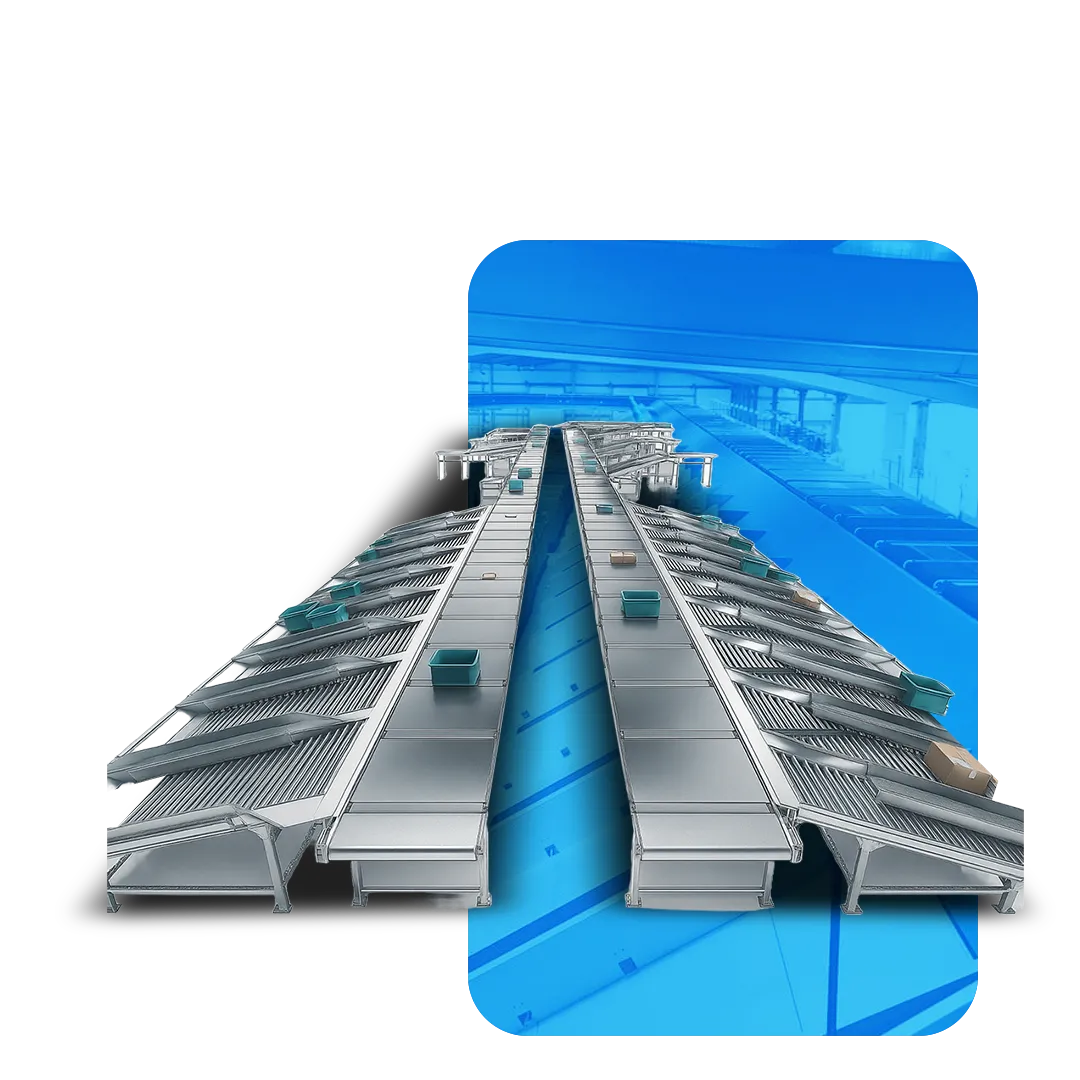

Wheel Sorter

A Wheel Sorter is a high-speed, precision sorting system used to divert products or parcels to multiple destinations on a conveyor line using angled rotating wheels. Known for its accuracy, speed, and smooth handling, the wheel sorter is ideal for sorting a variety of lightweight to medium-weight items such as cartons, polybags, boxes, and totes without causing product damage.

Wheel sorters can be configured as single-sided or dual-sided and integrated with barcode scanners, dimensioning systems, and warehouse management software (WMS) to enable smart, real-time sorting. This solution is perfect for e-commerce, courier, retail, and distribution centers looking to scale high-volume outbound operations efficiently.

High-Speed Sorting: Up to 100+ items per minute depending on layout.

Multi-Directional Sortation: Diverts items left, right, or straight based on logic input.

Modular Design: Easily integrates into existing conveyor infrastructure.

Low Impact Handling: Ideal for fragile or soft packages like polybags and apparel.

Barcode & Vision Ready: Integrates with scanners for dynamic sorting decisions.

Low Maintenance: Minimal moving parts compared to other sorters.

| Specification | Details |

|---|---|

| Throughput Rate | Up to 6000 parcels/hour (based on item size) |

| Item Size Range | 150 mm to 1000 mm (length) |

| Item Weight Range | 100 g to 35 kg |

| Sorting Directions | Left, Right, Straight (customizable chute positions) |

| Wheel Mechanism | Bi-directional angled wheels driven by servo motors |

| Conveyor Speed | 0.5 – 2 m/s |

| Control Interface | PLC with HMI / WMS connectivity |

| Noise Level | <70 dB (quiet operation) |

Applications

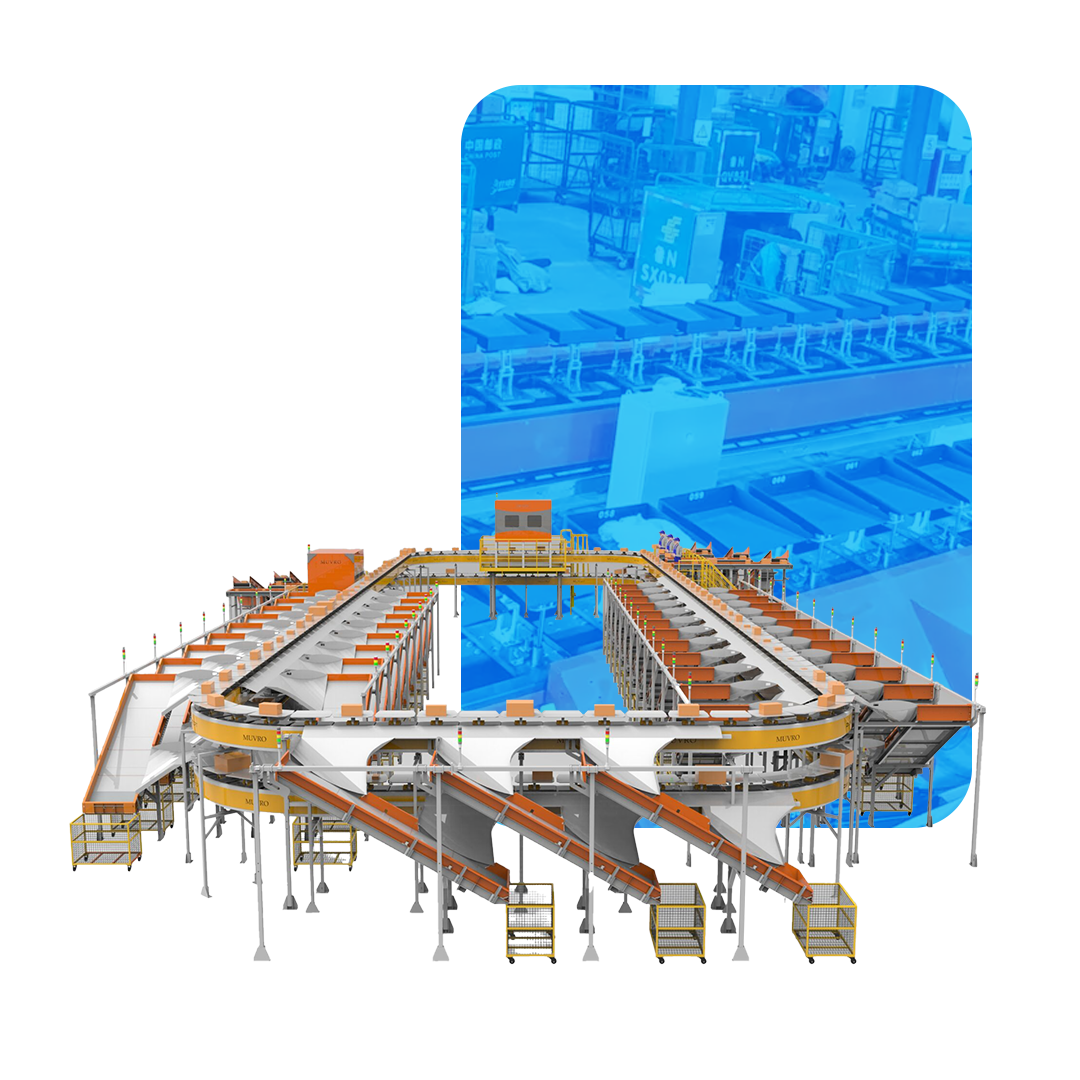

Cross Belt Sorter

A Cross Belt Sorter is a high-throughput, automated sortation system used to handle and direct diverse product types—from small polybags to large cartons—across multiple destinations with unmatched speed and precision. Each carrier on the sorter is equipped with a bidirectional mini belt conveyor that moves perpendicularly (crosswise) to the main travel direction, allowing for rapid and accurate item discharge into designated chutes or bins.

Cross belt sorters are known for their modular construction, quiet operation, and ability to handle mixed-size items at high speeds—making them essential for e-commerce fulfillment centers, courier hubs, postal facilities, and retail distribution warehouses. With seamless integration into WMS, barcode/RFID scanning, dimensioning, and labeling systems, they provide scalable, intelligent sorting capabilities tailored for modern supply chains.

High Throughput: Capable of sorting 8,000 – 25,000 parcels per hour.

Bidirectional Discharge: Allows sorting to either side for optimal space use.

Versatile Item Handling: Accommodates a wide range of sizes, shapes, and weights.

Accurate Item Tracking: Integrates with barcode/RFID scanners and vision systems.

Low Noise Operation: Designed for continuous use in quiet, indoor facilities.

Modular & Scalable Design: Easily expandable with minimal downtime.

| Specification | Details |

|---|---|

| Throughput | 8,000 – 25,000 items/hour |

| Item Size Range | 120 mm – 1200 mm (L) x 100 mm – 800 mm (W) |

| Max Item Weight | Up to 35 kg |

| Carrier Speed | 1.5 – 3.0 m/s |

| Discharge Directions | Left / Right / Both |

| Discharge Accuracy | ≥ 99.5% |

| Control Interface | PLC/PC-based, WMS/ERP integration |

| Noise Level | < 68 dB |

| Maintenance Access | Tool-free belt change and carrier service |

Applications

Flipper Sorter

A Flipper Sorter—also called a paddle sorter or tilt-tray wheel sorter—is a high-speed conveying device that diverts parcels, cartons, polybags, or totes by briefly lifting them on a set of powered belts or rollers and then “flipping” them sideways onto the correct take-away line. The brief pick-and-place action delivers precise, gentle handling even at high throughputs, making flipper sorters an ideal choice for facilities that process mixed SKUs, fragile packaging, or irregular shapes.

Typically mounted inside a slim, modular conveyor section, the flipper module works in concert with upstream barcode / RFID scanners and a warehouse control system (WCS) to execute real-time sorting decisions. The result is fast, quiet, low-maintenance sortation that fits neatly into existing conveyor lines without large footprint changes.

Rapid 90° Divergence – Pneumatic or servo-driven paddles flip items left or right in < 0.5 seconds.

Gentle Product Handling – Smooth lift-and-slide motion protects fragile or odd-shaped goods.

Compact, Drop-in Module – Fits standard 400–800 mm conveyor widths with minimal line disruption.

Bidirectional Sorting – Single unit diverts to either side; dual units can create multi-lane sortation.

Low Noise & Vibration – Belt-over-roller design keeps dB levels below 70 for operator comfort.

Smart Controls Ready – Integrates with PLC/WCS via Ethernet/IP, Profinet, or Modbus.

Tool-Free Service – Quick-release belts and easily accessible actuators shorten maintenance windows.

| Parameter | Value |

|---|---|

| Throughput | Up to 5 000 parcels/hour (size dependent) |

| Package Size | 150 × 100 mm min to 800 × 600 mm max |

| Max Weight | 30 kg per item |

| Conveyor Speed | 0.5 – 2.2 m/s (VFD-controlled) |

| Sort Angle | 90 ° left / right (custom 30–45 ° options) |

| Actuation | Servo or pneumatic cylinder |

| Module Length | 1 200 – 1 600 mm (model dependent) |

| Noise Level | < 70 dB at nominal speed |

| Power | 400 V AC 3-phase + 24 V DC control |

Applications

Vertical Sorter

A Vertical Sorter, also known as a Vertical Reciprocating Sorter (VRS) or Vertical Conveyor Sortation System, is a compact, high-throughput solution that sorts and transfers products vertically across multiple levels. Ideal for facilities with space constraints, this sorter allows for fast and efficient upward or downward movement of goods such as cartons, totes, polybags, and trays to designated conveyor lines or floors.

Designed with a reciprocating lift mechanism and integrated diverters, vertical sorters are widely used in multi-level warehouses, mezzanine-based fulfillment centers, and e-commerce hubs to streamline sortation with minimal horizontal space usage. They support in-line, up-feed, or down-feed layouts and are compatible with barcode/RFID scanning for intelligent routing.

Vertical Space Optimization – Utilizes height for sortation, ideal for multi-floor layouts.

High-Speed Reciprocation – Fast elevator-style mechanism handles continuous movement.

Multi-Level Sorting – Capable of sorting to multiple discharge conveyors or floors.

Compact Footprint – Minimal horizontal space required for installation.

Barcode & WCS Integration – Smart item tracking and dynamic destination control.

Safe, Enclosed Design – Includes interlocks, fencing, and emergency stop systems.

Energy Efficient – Operates on demand with reduced idle energy consumption.

| Parameter | Value |

|---|---|

| Throughput | Up to 3,000 items/hour |

| Travel Height | Up to 12 meters (customizable) |

| Lift Speed | 0.5 – 1.5 m/s |

| Package Size | 150 × 100 mm to 800 × 600 mm |

| Max Load per Carrier | Up to 30–50 kg |

| Number of Sort Levels | Up to 10+ discharge points |

| Sort Accuracy | ≥ 99.5% |

| Control System | PLC + HMI with WCS/WMS connectivity |

| Safety Compliance | CE / ISO 13849 / UL Standards |

Applications

Robot Sorter

A Robot Sorter is an intelligent, AI-powered automation system that uses robotic arms, vision systems, and AI algorithms to identify, pick, and sort products with high accuracy and flexibility. Unlike traditional fixed sorters (wheel, cross-belt, flipper), robot sorters offer dynamic, SKU-agnostic sorting, making them ideal for operations with frequent product variations, smaller batch sizes, or irregular item shapes.

Equipped with grippers or suction end-effectors and advanced vision systems (2D/3D cameras, AI-based object recognition), these robots can sort items based on size, shape, barcode, weight, color, or destination, ensuring high sorting accuracy with minimal mechanical complexity. They’re commonly deployed in e-commerce, retail, post & parcel, and manufacturing environments where space is limited but versatility and speed are critical.

AI Vision-Based Sorting – Identifies and sorts items using advanced machine learning and 3D vision.

Flexible Product Handling – Sorts boxes, pouches, polybags, irregular items, and fragile goods.

High Sorting Accuracy – Consistent performance even with mixed and unstructured product flow.

Compact Footprint – Can be deployed in smaller spaces compared to traditional sorters.

Multi-Destination Capability – Sorts items to multiple bins, chutes, conveyors, or totes.

Self-Learning Algorithms – Improves over time using AI for accuracy and pattern optimization.

Easy Integration – Connects with WMS/WCS, barcode/RFID scanners, and conveyors.

| Specification | Details |

|---|---|

| Payload Capacity | 0.1 – 15 kg (application dependent) |

| Vision System | 2D/3D AI camera system with object recognition |

| Sorting Targets | Up to 24+ destinations (chutes, bins, totes) |

| Item Size Range | 100 mm – 600 mm (L) |

| Item Type Compatibility | Polybags, cartons, bottles, pouches, irregular items |

| Repeatability | ±0.1 mm |

| Control Interface | PLC / ROS / API-based integration with WMS |

| Safety Features | Light curtains, collaborative options available |